2014/30/EU Electromagnetic Compatibility

EU Safety Standards & Directives

The EMC Directive 2014/30/EU is a wide ranging document which applies to “apparatus”. Everything electrical or electronic is covered, unless it appears in the exclusion list. (Guidance Document available form the www.ec.europa.eu web site).

This one of the most ignored Directives, for machines, in my experience, over the last 20 years. It is very convenient to brush it aside when its importance is not fully appreciated or understood. It applies to 'apparatus'. A machine is an 'apparatus'. Article 3 of 2014/30/EU gives this definition;

'apparatus' means any finished appliance or combination thereof made available on the market as a single functional unit, intended for the end-user and liable to generate electromagnetic disturbance, or the performance of which is liable to be affected by such disturbance;

2014/30/EU Electromagnetic Compatibility includes the following;

- This Directive shall apply to equipment as defined in Article 3. (see directive for full list)

- This Directive shall not apply to:

- equipment covered by Directive 1999/5/EC;

- aeronautical products, parts and appliances as referred to in Regulation (EC) No 216/2008 of the European Parliament and of the Council of 20 February 2008 on common rules in the field of civil aviation and establishing a European Aviation Safety Agency, and repealing Council Directive 91/670/EEC, Regulation (EC) No 1592/2002 and Directive 2004/36/EC (9);

- radio equipment used by radio amateurs within the meaning of the Radio Regulations adopted in the framework of the Constitution of the International Telecommunication Union and the Convention of the International Telecommunication Union (10), unless the equipment is made available on the market;

- equipment the inherent nature of the physical characteristics of which is such that:

- it is incapable of generating or contributing to electromagnetic emissions which exceed a level allowing radio and telecommunication equipment and other equipment to operate as intended; and

- it operates without unacceptable degradation in the presence of the electromagnetic disturbance normally consequent upon its intended use;

- custom built evaluation kits destined for professionals to be used solely at research and development facilities for such purposes.

- Where, for the equipment referred to in paragraph 1, the essential requirements set out in Annex I are wholly or partly laid down more specifically by other Union legislation, this Directive shall not apply, or shall cease to apply, to that equipment

- This Directive shall not affect the application of Union or national legislation regulating the safety of equipment.

The 2014/30/EU Electromagnetic Compatibility Directives objective is to ensure the product (apparatus) will function without disturbance in its intended environment. Will not interfere with intentional communications.

Split into two separate disciplines, neither of which are related to the other;

Emissions – (will not interfere with intentional communications)

Many devices (apparatus) in all parts of the world,have had to meet emission requirements for a long time. Commercially based upon CISPR 16 (Comité International Spécial des Perturbations Radioélectriques - International Special Committee on Radio Interference) measurement methods. Radiated and Conducted Emissions are addressed.

The test methods required by different parts of the world may not be the same, or the limits may not be the same. It is unlikely that the differences would be significant but would have to be assessed and noted.

Immunity – (will operate without disturbance in its intended environment)

Still relatively unique to the EU, requiring products (apparatus) to be immune to specific phenomena. Outside of the EU, the rest of the world has not put the same importance on immunity testing, in some cases not considering it necessary at all.

The lack of immunity testing is the difference between a CE marked product and a non CE marked product. The manufacturer selecting a sub system to be integrated into a machine, needs to ensure the component/sub system has been correctly CE Marked (where appropriate) and obtain a copy of the Declaration of Conformity.

EMC Declarations of Conformity will need to be assessed for accuracy. The most common error is the dated references of the standards or the wrong standard has been quoted. In North America it is quite common to obtain a DoC from the manufacturer, however the DoC is out of date.

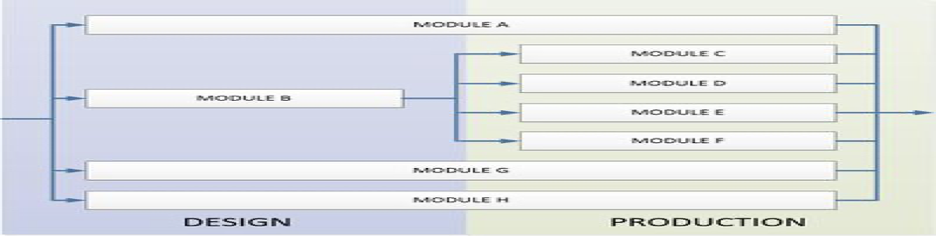

Conformity Assessment Procedures

The majority of manufacturers follow Annex II, Module A: Internal Production Control, to demonstrate compliance. It requires the manufacturer to perform an electromagnetic compatibility assessment to meet the essential requirements of the EMC Directive.

Essential Requirements;

1. General requirements

Equipment shall be so designed and manufactured, having regard to the state of the art, as to ensure that:

(a) the electromagnetic disturbance generated does not exceed the level above which radio and telecommunications equipment or other equipment cannot operate as intended;

(b) it has a level of immunity to the electromagnetic disturbance to be expected in its intended use which allows it to operate without unacceptable degradation of its intended use.

2. Specific requirements for fixed installations

Installation and intended use of components

A fixed installation shall be installed applying good engineering practices and respecting the information on the intended use of its components, with a view to meeting the essential requirements set out in point 1.

Both points 1 and 2 require Technical Documentation – Technical File (EMC Directive Annex 2).

Small products would be evaluated against the appropriate Harmonised Standard. This is always the best advice for manufacturers of small products. Meeting the appropriate Harmonised Standard gives an immediate presumption of conformance, that really can not be questioned.

EMC Testing of Machines

A majority of EMC test standards address small products. The standards require the use of shielded enclosures and specialized test areas. Often not at all suitable to large size machinery. Test facilities often do not have the correct capacity for three phase power requirements.

Moving the machine to a test facility is expensive and the time required to set up the machine would attract test facility fees. Not at all, an affordable solution.

The manufacturer is mandated to perform an Electromagnetic Compatibility assessment of the machine (apparatus). The assessment needs to be reasonable and defendable (should it be necessary), based on recognized, acceptable and affordable methods (A lot of statements are being made about SME - Small and Medium Enterprises).

Many approval companies offer “On Site” or “In Situ” assessments to at least profile an overall limited EMC performance of the product (apparatus). Any of these test programs is a good assessment and much, much better than a purely theoretical justification. However the assessment needs to be justified in an EMC Technical File, in line with the requirements of Annex II, Module A, point 3 (Many approval companies do not offer an EMC Technical File).

EMC Standards for Machines

It is important to reference a number of Harmonised Standards when discussing the EMC assessment. Selecting the appropriate standard is vitally important. All EU approved and Harmonised Standards are prefixed with “EN”, Euro Norm.

For a typical machine the following standards would be applicable;

Emissions;

EN55011:2016/A2:2021 Industrial, scientific and medical equipment - Radio-frequency disturbance characteristics - Limits and methods of measurement

This standard specifies two classes of machine(apparatus), Class A – industrial environments & Class B – Domestic environments. The classification for the environments is defined in the standards;

Class A equipment is equipment suitable for use in all locations other than those allocated in residential environments and those directly connected to a low voltage power supply network which supplies buildings used for domestic purposes.

Class B equipment is equipment suitable for use in locations in residential environments and in establishments directly connected to a low voltage power supply network which supplies buildings used for domestic purposes.

Immunity;

EN61000-6-2:2019 Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity standard for industrial environments

This standard is exclusive to industrial environments. It is a generic standard, this is used when a more specific standard does not exist.

It is extremely unlikely that all of the listed tests can be applied to an “on site” test, it is therefore vitally important the justification is outlined in the EMC Technical File.

The above standards are used for guidance during the “On Site” evaluation – only guidance because it is not possible to have laboratory conditions for an “On-Site” evaluation. The Declaration of Conformity CAN NOT state compliance to the standards for the above reason. The Technical File is used to justify the differences.

Technical Documentation

A mandatory requirement of the 2014/30/EU Electromagnetic Compatibility Directive. It shall include;

An example front page from a Technical File

This is similar to the Machinery Directive, but has different emphasis on the content.

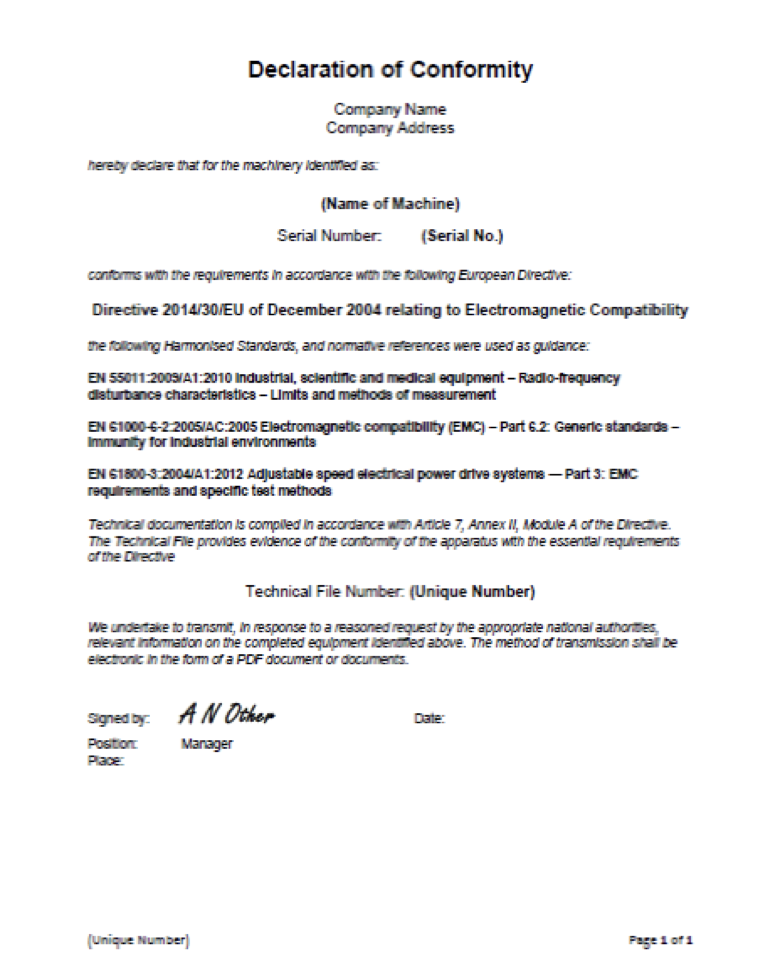

Declaration of Conformity (DoC)

Annex IV of the 2014/30/EU Electromagnetic Compatibility Directive gives details to the content of the DoC;

- Apparatus model/Product (product, type, batch or serial number):

- Name and address of the manufacturer or his authorised representative:

- This declaration of conformity is issued under the sole responsibility of the manufacturer.

- Object of the declaration (identification of apparatus allowing traceability; it may include a colour image of sufficient clarity where necessary for the identification of the apparatus):

- The object of the declaration described above is in conformity with the relevant Union harmonisation legislation:

- References to the relevant harmonised standards used, including the date of the standard, or references to the other technical specifications, including the date of the specification, in relation to which conformity is declared:

- Where applicable, the notified body … (name, number) performed … (description of intervention) and issued the certificate:

- 8. Additional information:

Signed for and on behalf of: (place and date of issue): (name, function) (signature):

The content of a DoC is very clear, there is no reason why a DoC for any of the CE Marking Directives should be incorrect.

Basic EMC Declaration of Conformity;

This DoC is for a Machine that has been assessed using “on site” test results and a Technical File.

Common EMC Mistakes made by integrators

Making rookie mistakes can add substantial cost.

- Not following Component/Sub system manufacturers installation instructions

- Not implementing “Good EMC Practice” with layout and cable routing

- Inadequate Ground/earthing practices

- Not using shielded cables where necessary

- Not terminating shielded cables correctly

- Signal segregation within electrical cabinet

The list above is an example on the type of measures that can affect the EMC performance of a product.